By Diane Harris, HQ Stitch Brand Ambassador

The difference between sewing with a dual-feed accessory and a regular presser foot is significant, and it’s worth making sure you understand the difference. Knowing when to perform each kind of sewing will make your work more accurate, and I think that makes creating more fun.

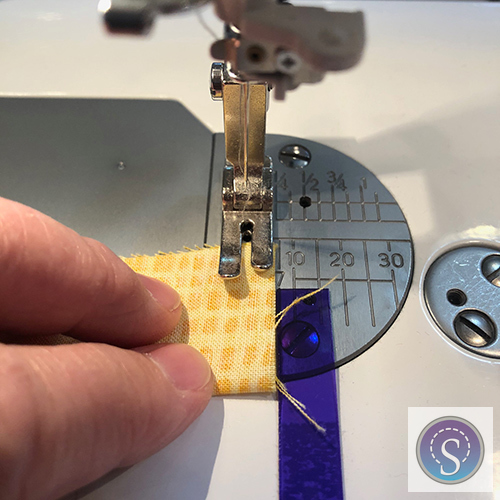

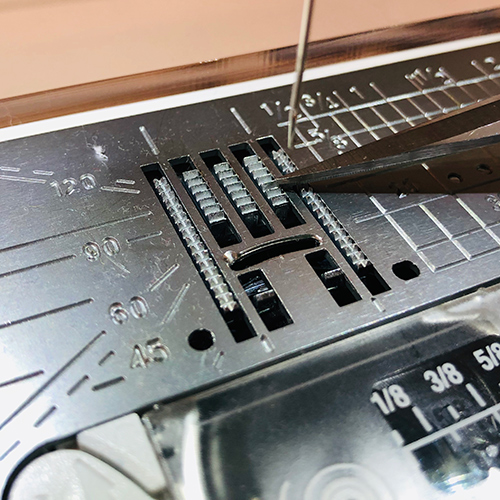

When you use a regular presser foot (any type that is not a dual-feed foot), the layers are fed under the needle at a slightly different rate. The feed dogs in the machine (shown below) do the work of pulling everything along, and since they touch only the bottom layer, that layer is pulled through a little more quickly than the upper layer.

Let’s say you’re sewing a very long seam, such as a quilt border, and you start with two pieces (the quilt top and the border strip) exactly the same length. By the time you get to the end, the bottom one will be shorter than the top one, as shown below. The feed dogs have pulled the bottom layer through more quickly than the top layer. And just a few threads every couple of inches quickly adds up.

There are a few things you can do to avoid this problem. The first one is to pin at short intervals. I always find the center of the quilt top and the border strip (just fold in half and make a crease with your fingernail) and pin the centers together. I also pin at each end. Then I pin at intervals of about 4″ or less.

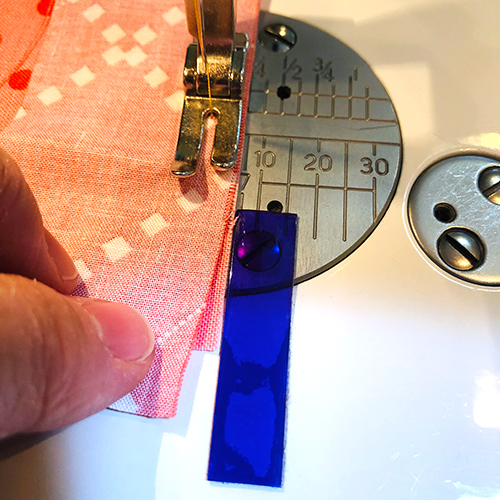

The second thing that will really help is to use a dual-feed foot on your machine. You may have heard it called a walking foot. The terms are interchangeable.

A dual-feed foot is essentially feed dogs for the top layer being sewn. The dual-feed’s feed dogs pull on the top layer at the same rate as the other feed dogs pull on the bottom layer, so that when you get to the end of a long seam, the top and bottom pieces will still match up.

You may be wondering why we don’t just use the dual-feed all the time. My experience is that most machines just sew better with a regular foot. For ordinary sewing, I prefer not to have a walking foot attached. For one thing, I have better visibility without the dual-feed attachment.

Secondly, a regular foot holds the patchwork a little more securely than a walking foot. There seems to be more jumping around with a dual-feed than with a regular stationary foot. These issues mean that I get along best if I only use the dual-feed when I’m sewing long seams. But for those times, the dual-feed accessory is indispensable.

And here’s a little secret:

You can ease in a too-large patch with a regular foot. For example, if you have a quilt section that is 31″ long, and you need to sew a strip to it that is 30-1/2″ long, if you match up the ends and sew with the longer part on the bottom against the feed dogs, the machine will automatically ease in the fullness.

Now generally, you want to make accurate patchwork so the parts all fit together nicely, but let’s be honest. Sometimes things don’t fit. Sometimes you have to do some easing, and now you know how.

HQ Stitch Dual-Feed

On the HQ Stitch 710, the Dual-Feed Foot Holder and the Dual-Feed Foot are included. The Dual-Feed Straight-Stitch Foot and the Dual-Feed 1/4″ Seam Foot are optional accessories.

On the HQ Stitch 510, the Even-Feed Foot is an optional accessory.

On the HQ Stitch 210, a Convertible Even-Feed Foot is an optional accessory.

I want to fmq with rulers. Which ruler foot do I use? All the ruler feet I find are for long arms.