By Diane Harris, HQ Stitch Brand Ambassador

Earlier this month I visited Massachusetts and New Hampshire to do programs for two quilt guilds there. I had a free day between them and my hostess sweetly offered to take me wherever I wanted to go.

I opted for the textile mills in Lowell, Mass, and I wasn’t disappointed. You could write volumes to cover this part of American history, but I’ll sum it up like this:

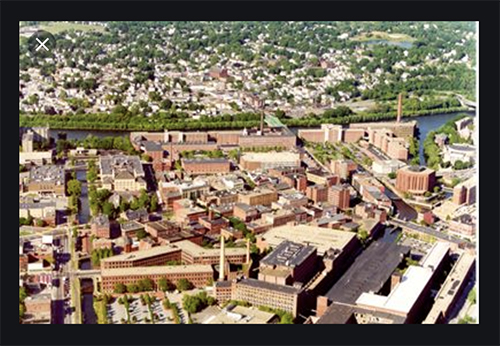

Lowell was the heart of the textile business as the Industrial Revolution swept America in the first half of the 1800s. The process of manufacturing cloth, i.e. spinning and weaving, came under one roof in the “Lowell system.” The first mill was built in 1814, and between 1820 and 1840 the number of people who worked in manufacturing increased by a factor of eight.

The Lowell mills hired women as their labor force. They were mostly single and between ages 15 and 35. They could be paid less than men and could be “more easily controlled…”. They became known as “mill girls,” working 12 hour days and maintaining a strict moral code.

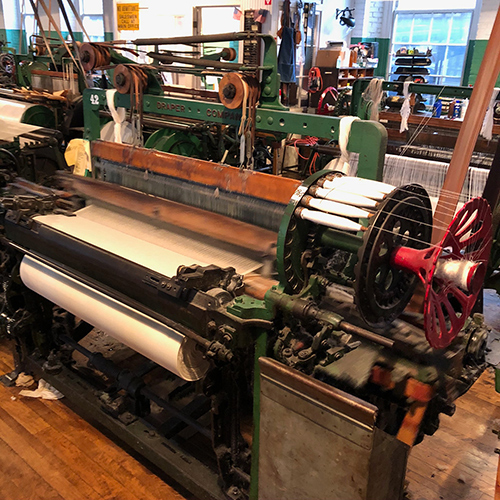

Visitors to the Boott Cotton Mills are treated to actual working looms, which make a terrible racket. With about 10 machines running, the noise was deafening, and you can only imagine how it would have been with all of them fired up.

I’d never understood how antique bobbins fit into the making of cloth, but now I do! Do you see the white thread wound onto bobbins at the left in the photo above?

Here’s a better shot of the individual loom. An interesting fact is that all those belts, of which many thousands were needed, came from the hides of bison killed on the great plains. (That’s where I live!)

Running the looms means that a lot of cloth is made, and it’s for sale in the gift shops for just $3.50 per yard. Of course I got some! Mine looks like toweling, and I think I’ll sew it into a souvenir of this trip, or maybe into a mug rug for my hostess.

Another tidbit: there was never an easy answer to the questions I asked of the park ranger, because the technology kept changing and advancing. But they had a cool model of how it worked at one time:

The process started with spinning on the bottom floor, and each subsequent step was on the next floor up. The actual looms, which wove the fibers into fabric, lived on the top floor of the mill.

There was just so much to see and to learn. The huge brick buildings in Lowell never seem to end, but now they’ve been converted into museums, or storage or offices, or trendy lofts on the Merrimack River.

I didn’t come close to getting my fill or to learning all there is to know.

I think Lowell would make a great trip for quilters some day. It’s fascinating to stand in between those two-hundred-year-old buildings and think of all the stories they could tell.

Loved reading about your trip and the textile history!

Great! Story, I’ve always been interested in the weaving of cloth. As a fabric-addict this was very exciting. Please continue bring stories like this.